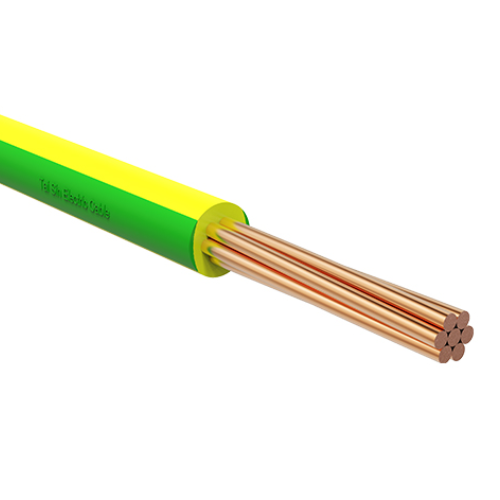

Figure 1: Prefabricated Branch Cable System

“Prefabricated Branch Cable” provide following advantages over traditional cables:

Labour Time and Cost

Tap off tasks such as splicing and jointing are already being carried out during manufacturing process in the factory. As need to perform these tasks on-site is eliminated, so time savings would be greater than 50%. Moreover, the availability of skilled labour to perform tap off tasks is no more mandatory, which results into a significant reduction in manpower requirements.

Material Cost

Tap off tasks such as splicing and jointing are already being carried out during manufacturing process in the factory. As need to perform these tasks on-site is eliminated, so time savings would be greater than 50%. Moreover, the availability of skilled labour to perform tap off tasks is no more mandatory, which results into a significant reduction in manpower requirements.

Reliability Enhancement

Tap off tasks such as splicing and jointing are already being carried out during manufacturing process in the factory. As need to perform these tasks on-site is eliminated, so time savings would be greater than 50%. Moreover, the availability of skilled labour to perform tap off tasks is no more mandatory, which results into a significant reduction in manpower requirements.

Testing & Standards

Tap off tasks such as splicing and jointing are already being carried out during manufacturing process in the factory. As need to perform these tasks on-site is eliminated, so time savings would be greater than 50%. Moreover, the availability of skilled labour to perform tap off tasks is no more mandatory, which results into a significant reduction in manpower requirements.